1. Convenient software, Embedded Linux System of the machine, stable industry main board, independent operation, no need external computer, operation easier and more convenient, learn fast.

2. In-build touch screen, no need external monitor, room saved, more convenient operation, USB mouse supported as well.

3. Top and bottom two vision cameras, correct the position of each components, you can view the vision image from screen for every components.(max component size 22*22mm)

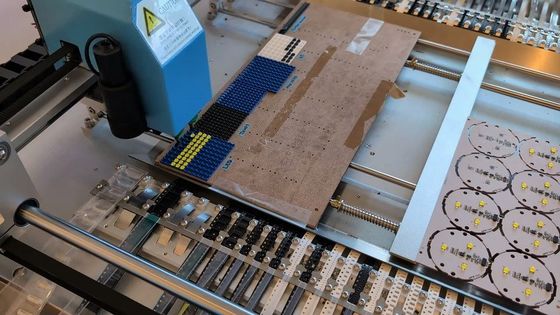

4. It has flexible PCB clamping fixture, suitable for different size of PCB.

5. It supported custom IC tray, IC tray can be fixed on machine table.

6. Two mounting heads with 2pcs Juki Nozzles, Juki nozzle inside magnet, so it can be removed by finger, no need to disassemble with wrench, nozzles rotation angle -180 degree to +180 degree.

7. All-in-one machine, 29pcs feeders included in machine, no need to buy other parts, machine is ready to work.

8. Z axis detection, machine's pull needle automatically return to origin to avoid nozzles broken.

9. Max height component support 5mm.

10. Closed-loop control, X,Y Axis with encoder, not out of step.

11. PCB calibrated by two components position, then rest components will be calibrated automatically.

12. Auto calibrate mark 2 points, it will be auto calibration before every running, make sure every PCB mounting precisely.

13. With vacuum detection, with automatic feeding, if one component suck crooked, it will automatically throw it to deposit area, then pick a new one to mount again.

14. With vision detection, camera will auto correction component angle and place on PCB board right place. If heads not picking up components, camera will detect it and go back to pick again, 3 times not picking, machine will alarm and stop, after supply material, then continue working, no need to start over again.

15. Comes with convert tool (PC version), edit work file in computer and load work file into machine by USB port, quick and convenient.

16. Support panelized boards.

17. If you don't have PCB file, you can create a new work file to program in machine directly.

18. Support single step.

19. Support cut tapes/ bulk material/ tube material.

Why choose Charmhigh?

1.Professional desgin and room saved.

2.User friendly operation, no need professional SMT engineer, entry-level device

3.One machine - Integrated operation, no need extra pump or PC or any supporting facility

4.High accuracy and reliability,make up the defection of manual work

5.Cost efficient, reduce expense to own a professional automatic SMT production line

6.International express with door to door service,3-5 working days delivery

7.Especial for laboratory research and development,samples,to avoid any patents and designs revealment.

8.One machine equal to 5 soldering staff, easy manage and cost-saved. Good for small batch production.

9.Charmhigh Is factory supply, all of our machines parts are researched and manufacturing by ourselves. After-service spare parts never stop.

10. Charmhigh is a professional manufacturer of SMT Pick and Place machine since 2009. All the software are researched by ourselves.

Standard Accessories for CHMT48VB:

1) Pick and Place Machine CHMT48VB 1

2) Juki nozzle total 4pcs (503, 504, 505, 506 size)

3) 8G USB driver 1

4) Power Cord 1

5) Pull needle 2

6) Coil for pull pin1

7) Camera positioning adjust black board 1

8) Hex wrench 6

9) Tweezers 1

10) Brush 1

11) Pen for touch screen 1

12) Fixture for IC tray 4

13) Grease 1

14) English user manual 1

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!