Highest Configuration 6 Heads SMT pick and place machine Robot

3 Pieces Auto PCB Conveyor, Double Y axis, 6 Heads 50 Feeders, Servo Motor, Automatic Nozzle Change, Higher accuracy CPK test passed, 0201 support, IPC9850: 13400CPH. CPK≥1.0 (X Y)

Medium SMT Production line, For PCBA SMT assembly line

This is an updated model CHM-751 from Charmhigh with economic price, it has high configuration and higher preicision, if you want a high precision machine with a economic price, this one is your best choice! This model has 3 pieces auto PCB conveyor, it can connect with SMT conveyor desk and reflow oven, delivery PCB into reflow oven.

Introduction:

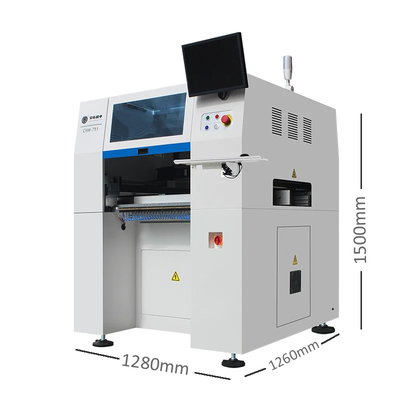

1. Model number: CHM-751

2. Brand: Charmhigh

3. Main configuration: High precision CPK test passed + 0201 support + Auto PCB conveyor + CPK test passed + Auto nozzle change + Max speed 18400 CPH + 6 heads 50 feeders + double Y axis + Ball screw with + Servor motor + 9 cameras + Yamaha feeders + intelligent software

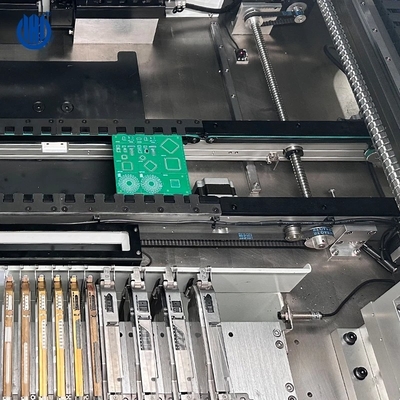

4. Max PCB area: 400*350mm

5. Component: 0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.)

6. Dimension: 1280mm(L)×1190mm(W)×1470mm(H)

7. Lead time: 5-7 working days

8. Delivery: by air, by sea, or pick up from our factory, or ship to shipping agent

9. Payment method: wire transfer (T/T); credit card; W/U

10. Packing: plywood box

11. HS code: 8479.89.62.00 (Pick and place machine)

CHM-751 catalog download: CHM-751 - Catalog.pdf

Highlight:

1. Thermal Compensation

2. Support CPK test, 0201 perfect mounting

3. Built-in Vacuum Pump

4. Automatic nozzle change (19 sets nozzle library)

5. PCB Support Device

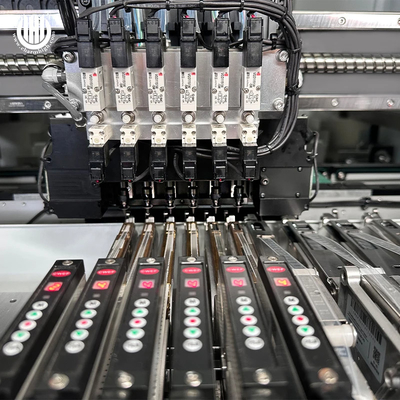

6. 6 head + 50 Yamaha feeder stacks + 9 cameras

7. Double Y axis with grinding screw, y axis with servo motors

For more machine features, please consult our account manager

| CHM-751 Specifications |

| Dimensions |

1280mm(L)×1190mm(W)×1470mm(H) |

| Weight |

670kg |

| Power Supply |

AC220V (50Hz, single phase), 2.8kW |

| Air Supply |

0.5MPa ~0.7MPa |

| Vacuum Generation |

Built-in vacuum pump |

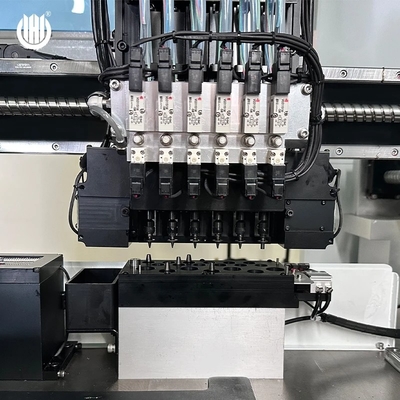

| Mounting Head Quantity |

6 heads |

| Mounting Speed |

18400CPH (optimal) ; IPC9850: 13400CPH |

| Mounting Accuracy |

(XY)±0.05mm, CPK≥1.0 |

| Component Height |

12mm |

| Component Type |

0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

| PCB Thickness |

0.6mm~3.5mm |

| PCB Size |

400mm(L)×350mm(W) |

| PCB Conveying |

3-section-rail automatic conveying, PCB support |

| Nozzle Change |

Automatic nozzle change (19-hole nozzle library) |

| Control System |

Built-in industrial computer (Windows 7) equipped with monitor, keyboard, and mouse |

| Drive System |

X&Y axis driven by servo motors (Y axis by double motors);

adopting flexible S-curve acceleration and deceleration |

| Transmission System |

Ground Ball screw + linear guide (Y axis with double screws) |

| Feeding System |

50 Yamaha 8mm standard pneumatic / electric feeder stacks

(also suitable for IC tray and stick feeder) |

| Vision System |

Snapshot camera×6 (component size applicable: 16mm×16mm);

IC camera×1 (component size applicable: 36mm×36mm);

Mark camera×2 |

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support & Contact:

Kimi Liu

Charmhigh Technology Limited

Mob/ WhatsApp: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us in YouTube: https://www.youtube.com/c/KimiLiuCharmhigh/videos

If you want to see more information and videos, please contact us by E-mail.

We will response you at the first time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!