Full automatic rail reflow oven + PC control 6 temperature zones (up6+down6)

Lead-free SMT Reflow Oven PC6635 soldering machine

2200*350mm 6 Zones 5KW Soldering Welding Machine

PC6635 catalog download: PC6635 reflow oven - Instruction.pdf

Technical Paramater for PC6635

| Model |

PC6635 (PC, up6+down6, 350mm width) |

| Heating part parameter |

| Heating zone |

up6 + down6 |

| Heating length |

2200mm |

| Cooling zone |

2 |

| Conveyor parameter |

| Max.width of PCB |

Mesh width 350mm, Rail adjustable 250mm |

| Conveyor direction |

L→R (R→L.option ) |

| Height of conveyor |

Mesh 880±20mm |

| Transport system |

Mesh conveyor+ Rail conveyor |

| Conveyor speed |

0-2000mm/min |

| Controlling parameter |

| Power supply |

5 wires 380V 50/60Hz |

| Power of start up |

24KW |

| Power of consumption of operation |

Approx.5-6KW |

| Control fashion |

Industrial PC + monitor |

| Warm-up time |

Around 20 mins |

| Range of temperature control |

Room Temperature-350℃ |

| Temperature control |

Industrial PC+Temp. module control, SSR Driver |

| Precision of temperature control |

± 1℃ |

| Temperature distributing error |

± 3℃ |

| Trouble alarm |

Abnormal temperature (ultra-high or ultra-low temperature after constant temperature) |

| Board drop alarm |

Option |

| Machine size&weight |

| Net weight |

Approx.400kg |

| Dimension(mm) L×W×H |

L3600×W700×H1430 |

Description for PC6635:

1.Patented heating wire technology with independent circulating air structure, top and bottom heating methods, high thermal efficiency, and rapid temperature rise, reaching the set working temperature from room temperature in approximately 20 minutes, with a temperature difference of less than 30°C between the set temperature and actual temperature in the welding area.

2.Equipped with a dedicated high-temperature motor from Taiwan San Yue, directly coupled to drive hot air heating, ensuring balanced hot air distribution, low noise, and minimal vibration, allowing 0201 components to remain in place during transportation.

3.Unique air duct design with imported snail shell air circulation and three-layer air distribution devices, providing uniform air circulation, large heat capacity, and separate heating for the preheating zone, temperature control zone, and welding zone with independent circulation and temperature control, each temperature zone controlled with an accuracy of ±1°C, and the furnace chamber is opened with a pneumatic top cover.

4.Standard configuration includes two forced cooling zones, with the cooling air temperature reaching as low as 5°C, and the cooling rate in the first cooling zone can reach -5°C/S. Effectively meets the requirements of various lead-free processes.

5.Suitable for adjusting the temperature curves of various models, with dual or triple welding zone configurations, eight-line PROFILE TEST with a minimum of 8°C, and continuous curve testing specifically tailored to lead-free soldering processes in Japan or Europe and America.

6.The latest design of dedicated transport guide rails, made of high-temperature resistant and wear-resistant aluminum alloy, ensuring high rigidity and no deformation.

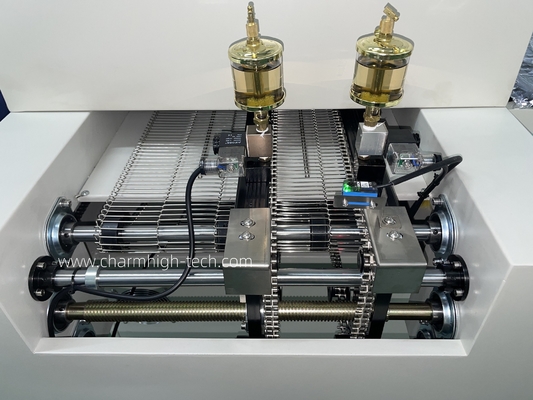

7.The transport system uses variable frequency speed control, driven by imported Japanese Dongchuan motors, with high-quality stainless steel chains and SUS316 material stainless steel mesh belts for synchronized transport, further ensuring stable transport. It is also equipped with an uninterruptible power supply (UPS) function, effectively preventing damage to PCBs inside the furnace due to sudden power outages.

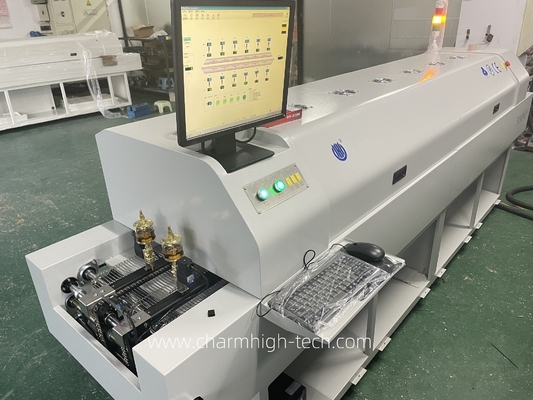

8.Controlled by an industrial computer, with a LCD monitor display and Windows 10 operating system, featuring flexible curve testing and powerful dynamic curve analysis capabilities, as well as the ability to print and save all data, meeting the requirements of lead-free processes.

All electrical components are made of imported parts, and all signal lines are shielded to ensure stable and reliable operation of the SMT24 for 24 hours a day, with a one-year warranty on the entire machine and lifetime maintenance.

100% Real Pictures of PC6635:

SMT Production Line Recommendations:

1.PCB loader

2.E6 solder paste printer

3.PCB conveyor

4.CHM551 pick and place machine - two units

5.PCB conveyor

6.PC6635 reflow oven with automatic rail+PC

7.PCB unloader

Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support:

Kimi Mob: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us in YouTube: https://www.youtube.com/@KimiLiuCharmhigh/videos

If you want to see more information and videos, please contact us by E-mail.

We will response you at the first time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!