4 heads 50 Feeders Table top CHM-650 SMT Pick and Place Machine

For high precision small batch production, 0201 mass production perfectly

Auto nozzle change, working with universal Yamaha feeders

Model: CHM-650

*4 Placement Heads with auto nozzle changer

*Support 50pcs Yamaha pneumatic& electric feeders

*Higher configuration with high accuracy, 0201 supported

*Comes with computer (monitor, Keyboard, USB mouse)

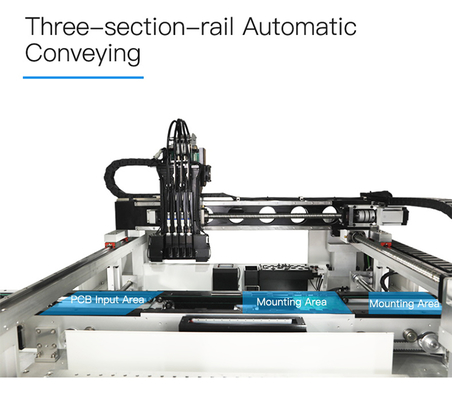

*Strong mechanical, 3-section PCB auto delivery, room saved

YouTube working video:

CHM-650 mounting 0201 0402 TQFP 128pin:

https://youtu.be/PdjjR7lc56Q

CHM-650 mix mounting:

https://www.youtube.com/watch?v=Hk0rwxEVXf8

CHM-650 working video from Bulgarian customer:

https://www.youtube.com/watch?v=50mu2rlPrrc

Real shot of CHM-650 4 heads pick and place robot at factory:

https://www.youtube.com/watch?v=R6UZqwV8Zvc

| CHM-650 Specifications |

| Dimensions |

1280mm(L)x1190mm(W)x1050mm(H) |

| Weight |

310kg |

| Power Supply |

AC220V (50Hz, 1 phase), 2.1kW |

| Air Supply |

0.5MPa ~ 0.7MPa |

| Vacuum Generation |

Vacuum generator |

| Mounting Head |

4 Heads |

| Mounting Speed |

9000cph(optimal) |

| Mounting Accuracy |

(XY) ±0.05mm; CPK≥1.0 |

| Control Accuracy |

5μm |

| Component Height |

12mm |

| Component Type |

0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.)

|

| PCB Thickness |

0.6mm~3.5mm |

| PCB Size |

400mm(L)x350mm(W) |

| PCB Conveying |

3-section-rail automatic conveying |

| Nozzle Change |

Automatic nozzle change (19-hole nozzle library) |

| Control System |

Built-in industrial computer (Windows system)

equipped with monitor, keyboard, and mouse

|

| Drive System |

X&Y axis driven by servo motors; adopting flexible S-curve acceleration and deceleration |

| Transmission System |

Ball screw + linear guide |

| Feeding System |

50 Yamaha 8mm standard pneumatic/electric feeder slots

(also suitable for IC tray and stick feeder)

|

| Vision System |

Snapshot camerax4 (component size applicable: 16mmx16mm);

IC camerax1 (component size applicable: 36mmx36mm);

Mark camerax2

|

Easy file programming:

Highlight:

1. Auto nozzle exchange, you don't need to change nozzle manually, very convenient!

2. Strong vision camera system, higher accurate, IC placecd more accurate, and min component 0201:

3. High configuration, long lifespan, Charmhigh provide strong mechanical.

Working with universal standard Yamaha Feeders:

Option:

1. 8mm/ 12mm /16mm /24mm /32mm /44mm electric feeder

2. 8x4mm / 12mm/ 16mm / 24mm /32mm / 44mm pneumatic feeder

3. Vibration feeder

Charmhigh SMT, factory supply, prompt delviery:

100% high feedback from customers:

Please note:

The pick and place machine is complete set with all accessories included in the package, machine ready to use!

The only thing you need to prepare is an external air compressor (supplying air for feeders, head vaccum, ANC, PCB stopper...).

Please purchase this machine with confidence. Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory direct supply with guarantee.

We provide online Q/A and troubleshooting support and technical advice service.

We provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support:

Kimi Liu: Mob/ WhatsApp: +8613510675756

E-mail: kimi@charmhigh-tech.com

Welcome to follow us on YouTube: https://www.youtube.com/@KimiLiuCharmhigh

If you want to know more information, please contact us by E-mail.

We will response you at the first time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!