CHM-T530P4 Introduction

Desktop SMT pick and place machine Charmhigh CHM-T530P4, 220v/110v

4 heads 30 feeders, for PCB assembly line

CHM-T530P4 main features

1. Model number: CHM-T530P4

2. Brand: Charmhigh

3. Main configuration: Desktop type + 4 Heads 30 feeders + built-in PC + Embedded Linux system + closed-loop control motor with encoder + 2 cameras + linear rail + auto calibrate PCB + touch screen

4. 4. Feeder: 2 options: Yamaha pneumatic feeder & Electric feeder (feeders purchase separately)

5. Max PCB area: 450*330mm

6. Component: 0402-5050, LED, SOT, SOP, QFN, BGA... etc.

7. Dimension: 1100mm(L)*700mm(W)*600mm(H)mm, AC220V/110V (50/60Hz)

8. Lead time: 2-3 working days

9. Delivery: by DHL or TNT / by air / by sea / pick up from our factory directly / send to China warehouse

10. Payment method: Wire transfer (T/T); PayPal; W/U

11. Packing: plywood box

CHM-T530P4 description

This CHMT530P4 is an updated desktop pick and place machine which work with Yamaha feeders.

It has 4 heads with 30pcs feeder slots, for small smt production is your good helper!

The operation system is industry level embedded Linux system, the main board of machine was researched by ourselves, which is more reliable than windows system, and life time is much longer.

CHMT530P4 using 502---507 different kinds of Juki nozzles, suitable for 0402,0603,0805-5050, LED, SOT, SOP, QFN, BGA, Diode, Transistor...etc, which can meet more customers' demand. Very good for small batch production or prototyping or education.

It has double vision cameras, which can auto calibrate the PCB before running, auto correction pick position and angle.

CHM-T530P4 Parameters

| Model |

CHM-T530P4 |

| XYZ Axis travel |

760mm(X)*650mm(Y)*20mm(Z)

Max height component:10mm

|

| PCB max size |

450mm(L)*330mm(W) |

| Support components |

0402-5050,LED, SOT, SOP, QFN,BGA etc. |

| Mounting speed |

- Without vision:5000cph

- With Vision:4000cph

|

| Precision |

±0.025mm |

| Placement head |

4 heads |

| Feeding system |

Support max 30pcs 8mm tape reels

*Feeder option: (Yamaha universal type)

1.electric feeder: 8mm (for 0402 etc)

2.pneumatic feeder: 8,12,16,24mm

3.vibration feeder(3 tubes/ 5 tubes)

- 11pcs front bulk material

- Support IC tray

|

| Vision detection |

Double cameras (up & down)

Up-looking camera max recognize range of component: 22*22mm

|

| Motor control |

- -XY Axis stepper motor with encoder with closed-loop control

- -Flexible S deceleration

- -Z Axis reset detection

|

| Components leakage detection |

Vacuum detection / vision detection |

| Main board |

High-reliability industry motherboard |

| Touch Screen |

Build-in 7 inches industry screen, no need external monitor or PC;

(support cold plug-in USB mouse)

|

| Operation system |

Embedded Linux system |

| External air source |

0.5 MPa |

| Power supply |

AC220V 50Hz / AC110V 60Hz |

| Dimension |

1100mm(L)*700mm(W)*600mm(H) |

| Power |

250W |

| Net weight |

125Kg |

Standard packing list for CHMT530P4:

1) Pick and Place Machine CHMT530P4: 1

2) Juki nozzle total 4pcs (503, 504, 505, 506 size)

3) 8G USB driver 1

4) Power Cord 1

5) Grease 1

6) Hex wrench 6

7) Tweezers 1

8) Brush 1

9) Additional belt set 1

10) Pen for touch screen 1

11) Fixture for IC tray 4

CHM-T530P4 adavantages:

1. Convenient software, Embedded Linux System of the machine, stable industry main board, independent operation, no need external computer, operation easier and more convenient, learn fast.

2. In-build touch screen, no need external monitor, room saved, more convenient operation, USB mouse supported as well.

3. Top and bottom two vision cameras, correct the position of each components, you can view the vision image from screen for every components.(max component size 22*22mm)

4. It has flexible PCB clamping fixture, suitable for different size of PCB, CHM-T530P4 max support PCB 450mm(L)*330mm(W).

5. It supported custom IC tray, IC tray can be fixed on machine table. Software max allow 20pcs tray.

6. Four mounting heads with 4pcs Juki Nozzles, Juki nozzle inside magnet, so it can be removed by finger, no need to disassemble with wrench, nozzles rotation angle -180 degree to +180 degree.

7. Work with Yamaha standard pneumatic feeders(8mm/12mm/16mm/24mm/vibration feeder) and Electronic feeders(8mm/12mm/16mm).

8. Z axis detection, placement heads can auto back to origin to prevent nozzles break.

9. Max height component support 10mm.

10. Closed-loop control, X,Y Axis with encoder, not out of step.

11. PCB calibrated by two components position, then rest components will be calibrated automatically.

12. Auto calibrate mark 2 points, it will be auto calibration before every running, make sure every PCB mounting precisely.

13. With vacuum detection, with automatic feeding, if one component suck crooked, it will automatically throw it to deposit area, then pick a new one to mount again.

14. With vision detection, camera will auto correction component angle and place on PCB board right place. If heads not picking up components, camera will detect it and go back to pick again, 3 times not picking, machine will alarm and stop, after supply material, then continue working, no need to start over again.

15. Comes with convert tool (PC version), edit work file in computer and load work file into machine by USB port, quick and convenient.

16. Support panelized boards.

17. If you don't have PCB file, you can create a new work file to program in machine directly.

18. Support single step.

19. Support cut tapes/ bulk material/ tube material.

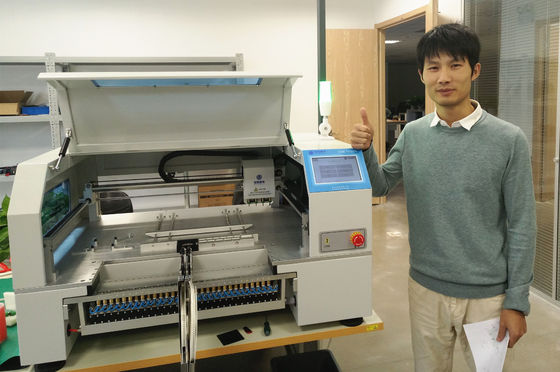

100% real photos:

Work with standard Yamaha feeders (electric feeder + pneumatic feeder)

SMT production line , PCB assembly line recommendation:

Touch Screen, USB mouse supported, easy software operation:

Place IC very accurate! Vision system with top and buttom two cameras:

Custom IC tray supported, cut tape supported:

Customer feedback:

Standard Juki nozzles: (Different types 503 504 505 506)

Welcome inquiries!

Please note:

The pick and place machine is complete set with all accessories included in the package, machine ready to use!

The only thing you need to prepare is an external air compressor with 8mm outer diameter pipe (supplying air for pneumatic feeders), inserting the pipe on the backside of machine.

Please purchase this machine with confidence.

Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory direct supply with guarantee.

We provide online Q/A and troubleshooting support and technical advice service.

We provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support:

Kimi's Mob/ WhatsApp: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us in YouTube: www.youtube.com/channel/UCKRczL5Hywx59M_2SWGJOsA/videos

If you want to know more information, please contact us by E-mail.

We will response you at the first time.

Why choose Charmhigh?

1.Professional design and room saved.

2.User friendly operation, no need professional SMT engineer, entry-level device

3.One machine - Integrated operation, no need extra pump or PC or any supporting facility.

4.Cost efficient, reduce expense to own a professional full automatic SMT production line.

5. It is very convenient to change machine replacement, easy to fix by self.

6.International express with door to door service, 6-8 working days delivery.

7.Especially for laboratory research and development, to protect your own design and patent.

8.One machine equal to 5 soldering staff, much higher efficient than manual work, easy manage and cost-saved. Good for small batch production.

9.Charmhigh Is factory supply, all of our machine parts are researched and manufacturing by ourselves. After-service spare parts never stop.

10. Charmhigh is a professional manufacturer of SMT Pick and Place machine since, first p&p released in 2011. All the software researched by ourselves, provided good after-sell service.

Q1: What is the lead time of your products? (How long do you need to prepare my goods?)

A: 2-3 days for 1-3 unit machine. 5-15 days for mass production orders (based on different quantities).

Q2: How will you deliver my goods to me?

A: We usually ship by international expresses such as DHL,UPS, FedEx, TNT to enable our customers get their

goods rapidly. For bigger quantity, ship by air or by sea.

Q3: How long do I need to wait before my goods arrive?

A: 3-7 days for international express. 5-8 days for air transportation. 20-40 days for sea transportation.

Q4: What is your product quality?

A: Our raw materials are purchased from qualified suppliers, the best qaulity in China. And our engineers all have over 20 years expereinces in Machinery, ensure good quality and functions. Now CharmHigh's Quality and feedback is better than other brands in China.

Standard package service:

The package of our P&Ps is standard export wooden package to avoid the damage during the transportation.

Transportation service:

For package below 300 kg , you can use DHL, Fedex or other express company, For large quantities, you could use sea delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!