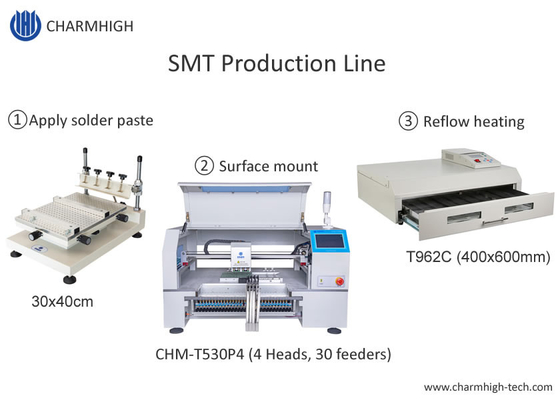

CHM-T530P4 SMT Pick and Place Machine / 3040 Stencil Printer / Reflow Oven T962C

Bentch top small SMT assembly line , very good for small batch production.

(CHARMHIGH) YOUTUBE CHANNEL:

www.youtube.com/channel/UCKRczL5Hywx59M_2SWGJOsA/videos

CHMT530P4 has 4 heads, mounting speed is faster. For small SMT production, it is your good helper!

The main board of machine was researched by ourselves, which is more reliable than windows system, and life time is much longer. CHMT530P4 using 502---506 different kinds of Juki nozzles, suitable for 0402, 0603, 0805-5050, SOP, QFN, LQFP, Diode, Transistor, BGA...etc, which can meet more customers' demand.

Machine uses embedded Linux operation system, This system runs stable with strong compatibility and powerful function. Machine has a in-build 7 inch full touch screen, external USB mouse also accepted. Very easy and convenient operation. You can get a quick start within half an hour.

It has double vision cameras, which can auto calibrate the PCB fiducial before running, auto correction pick position and angle.

Small SMT Production line:

1. 3040 stencil printer:

| Work table size |

300*400mm |

| Print size |

250*400mm |

| Max net frame size |

370*470mm |

| Printer way |

manual |

| Thickness of the substrates |

0-80mm |

| The workbench adjust volume |

10mm, Horizontal Angle adjustment |

| Printing platform height |

220mm |

| repeated accuracy |

+-0.01mm |

| locate mode |

Benchmark or hole shape |

| Dimension |

540*370*350 mm |

| Packing size |

630*450*480mm |

| Weight |

NW.22Kg GW.23Kg |

2. CHMT530P4 specification

| Dimensions |

1100mm(L)*700mm(W)*600mm(H) |

| Net Weight |

140kg |

| Power Supply |

AC220V (50Hz, single phase) /AC110V (60Hz, single phase); 400W |

| Air Supply |

0.5MPa ~0.7MPa |

| Vacuum Generation |

Built-in vacuum pump |

| Mounting Head |

4 heads |

| Mounting Speed |

8000cph(optimal without vision detection);

5500cph (optimal with vision detection) |

| Control Accuracy |

0.015mm |

| Component Type |

0402/0603 ~ 5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

| PCB Thickness |

0.6mm~3.5mm |

| PCB Size |

10mm(L)x10mm(W )~ 450*330mm |

| PCB Conveying |

Manual operation |

| Nozzle Change |

Manual operation |

| Control System |

Built-in computer (embedded Linux operating system),

7-inch touch screen |

| Drive System |

X&Y-axis driven by stepping motors in the way of closed-loop control;

Z-axis capable of reset detection;

all motors adopting flexible S-curve acceleration and deceleration

|

| Transmission System |

Synchronous belt + linear guide |

| Feeding System |

60 Yamaha 8mm standard pneumatic feeder stacks (also suitable for

Yamaha electric feeder, IC tray, and stick feeder), 11 preset general IC stacks,

work surface custom IC trays supported

|

| Vision System |

Up-looking camera for component automatic calibration

(component size applicable: 22mmx22mm); down-looking camera for PCB

calibration via Mark Point and component positioning

|

3. T962C Reflow oven

Effective Soldering max area: 400 x 600mm

Rated power: 2900W

Temperature Range: 0degC-280degC

Process cycle: 1~8 min

Voltage: 110V~240V

Frequency: 50Hz~60Hz

Product size: 684x504x225mm

Net weight: 25kg

Packing weight: 29kg

Pictures as follows:

Please note:

The pick and place machine is complete set with all accessories included in the package, machine ready to use!

The only thing you need to prepare is an external air compressor with 8mm outer diameter pipe (supplying air for pneumatic feeders), inserting the pipe on the backside of machine. Please purchase this machine with confidence. Enjoy with your pick and place machine!

Service & Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service. We always provide spare parts of machine, factory direct supply with guarantee. We provide online Q/A and troubleshooting support and technical advice service. We provide one to one after-sale service. Each machine 100% tested well before ship out.

Tech support:

Kimi's Mob/ WhatsApp: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us in YouTube: www.youtube.com/kimiLiuCharmhigh

If you want to know more information, please contact us by E-mail. We will response you at the first time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!