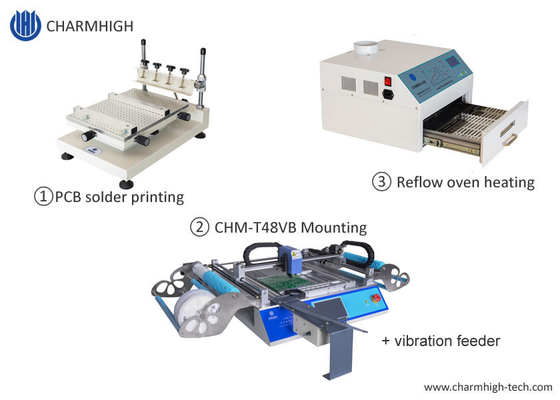

Stencil Printer 3040 / CHMT48VB+ Vibration Feeder, SMT assembly Line / Reflow Oven CHMRO-420

Best sale SMT Production line:

High precision 3040 Stencil printer + CHMT48VB 58 feeders + 2500w Reflow oven 420,

Free shipping DHL door to door shippping.

or you can arrange pick up machine from our factory directly.

Buy it from our online store with lowest price directly:

CHMT48VB + 3040 + 420: https://www.charmhigh-smt.com/sale-451236-hot-desktop-smt-production-line-chmt48vb-smt-pick-and-place-machine-3040-stencil-printer-420-reflow-oven.htm

Dear friends, here we recommend the best sale SMT production line combination for you, most cutomers like this set!

Stencil printer 3040 is the best quality in China with high feedback, 100% high feedback.

CHMT48VB sells very well and it has 58pcs feeders, which can meed more customers demand, it is very popular now!

And CHMRO-420 reflow oven is the best quality drawer type oven in China, it is better than other drawer type oven in China, we recommend!

Machine is completed, ready for work, each machine will be 100% tested well, QC passed.

Please purchase it with confidence.

Quality guarantee, quality is better than other brand machines.

Packing list:

CHMT48VB Desktop pick and place machine complete set ---- 1

Vibration Feeder for CHMT48VB ----------1

High precision stencill printer 3040 best quality ---- 1

2500W 300*300mm Infrarad + hot air reflow oven CHMRO-420 ---1

Small SMT Production line:

1. 3040 stencil printer:

| Work table size |

300*400mm |

| Print size |

250*400mm |

| Max net frame size |

370*470mm |

| Printer way |

manual |

| Thickness of the substrates |

0-80mm |

| The workbench adjust volume |

10mm, Horizontal Angle adjustment |

| Printing platform height |

220mm |

| repeated accuracy |

+-0.01mm |

| locate mode |

Benchmark or hole shape |

| Dimension |

540*370*350 mm |

| Packing size |

630*450*480mm |

| Weight |

NW.22Kg GW.23Kg |

2. CHMT48VB Main parameters

| Model |

CHM-T48VB |

| PCB area |

10mm*10mm - 345mm*355mm |

| X Y axis Travel |

510*460mm |

| Z axis moving range |

15mm (Highest component 5mm) |

| Placement heads |

2pcs, comes with 4 nozzles |

| Feeders |

Tape reel feeder 58pcs (left 29pcs + right 29pcs)

(8mm=44pcs, 12mm=8pcs, 16mm=4pcs, 24mm=2pcs,)

Front bulk IC feeder=14pcs, customs IC tray 20pcs

Tube feeder supported (option)

|

| Vision system |

Two cameras (up & down cameras) Vision max range 22*22mm |

| Drive |

Closed-loop control stepper servo drive system, make sure never lose step |

| Z axis self-return detection |

Yes, it prevent nozzles breaking |

| Pull pin self-return |

Yes, it prevent needle breaking |

| Leakage of material detection method |

Vacuum detection, vision detection |

| Touch screen |

7 inch industry touch screen |

| Main board |

Independent research industry main board |

| System |

Embedded Linux system |

| Mounting speed |

4000cph (vision off); 3000cph (vision on) |

| Mounting precision |

±0.025mm |

| Components |

0402-5050,SOP,QFN ..etc. |

| Machine dimension |

L 960mm* W 705mm* H 335mm |

| Vacuum pump |

-92KPA (2pcs,build-in, mute type) |

| External air source |

No need (machine build-in mute vacuum pump 2pcs) |

| External PC |

No need external PC (it has build-in computer) |

| Voltage |

220VAC (110VAC), 50Hz/60Hz |

| Net weight |

68kg |

| Gross weight |

85kg / 116*80*52cm |

3. CHMRO-420 Reflow oven parameter:

| Soldering max area |

270*270mm |

| Soldering way |

Hot air + IR mix |

| Rated power: |

2500w |

| Process Period: |

5- 10 min |

| Max temperature: |

300 degree |

| Temperature control accuracy |

±1 degree (constant temperature) |

| Welding type: |

Lead & Lead free |

| Power Supply: |

AC220V only /50HZ |

| Net weight |

22kg |

| Gross weight |

23kg |

| Item dimension |

405*420*255mm |

| Number of stored curves |

8 |

Pictures as follows:

1. Stencil printer Middle size 320*440mm

2. CHMT48VB, 58 feeders, with vibration feeder

Pick and place machine with Vision System

3. Reflow oven CHMRO-420:

Kindly note:

The pick and place machine is complete set with all accessories, all-in-one machine, ready to use!

You don't need to prepare other accessories, you can use it when you receive it.

Now enjoy with your pick and place machine!

Warranty:

The complete machine has a warranty period of 1 year from the time of purchase and lifetime service.

We always provide spare parts of machine, factory reliable direct supply.

We provide online Q/A and troubleshooting support and technical advice service.

Provide one to one after-sale service. Each machine 100% test well before send out.

Tech support:

Kimi

Mob: 0086 135 106 75756

Skype: kimiliu89

E-mail: kimi@charmhigh-tech.com

Welcome to follow us in YouTube: www.youtube.com/kimiLiuCharmhigh

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!